Built to climb: How AMTs helped power Delta to a century of flight and beyond

By Drake Castañeda

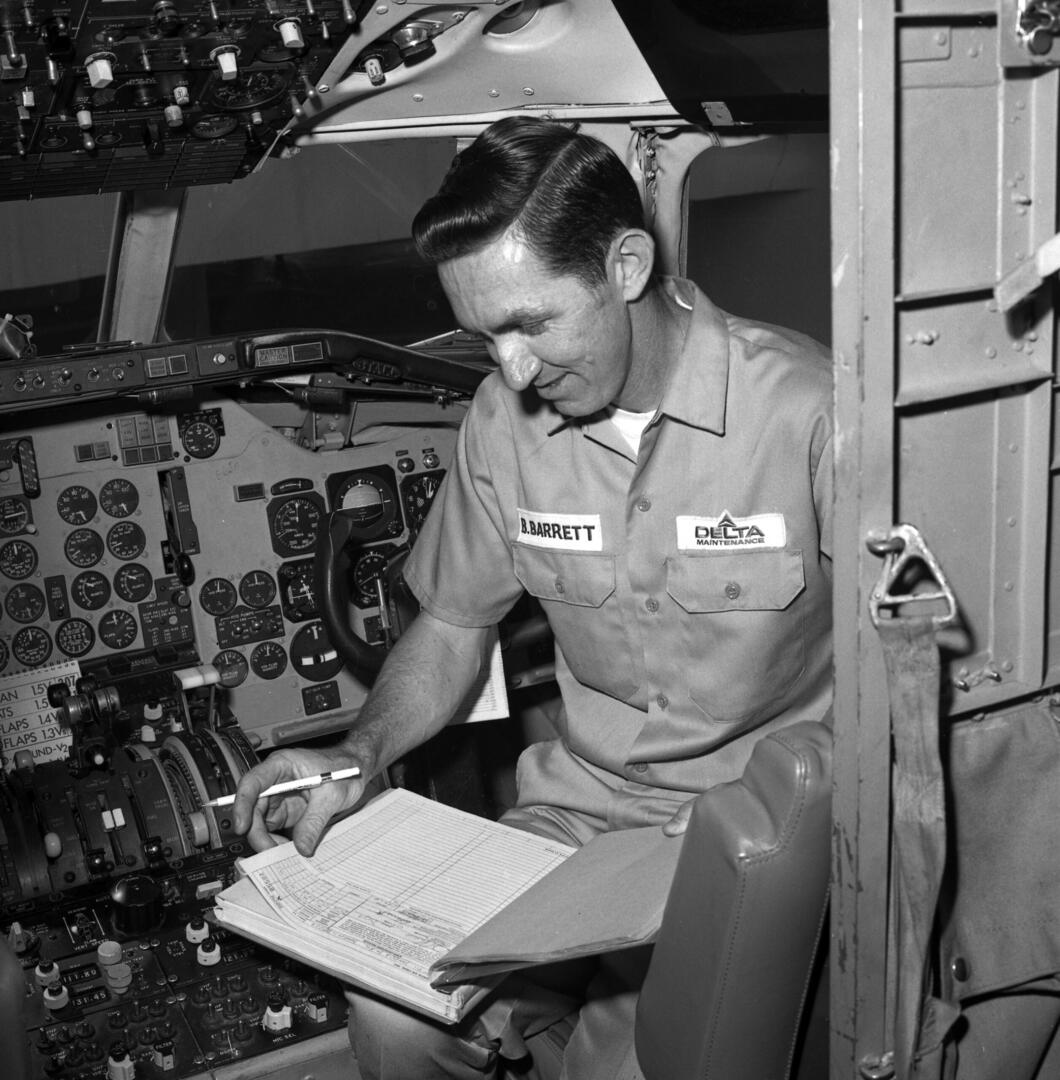

Every May 24, Delta honors National Aviation Maintenance Technician Day by celebrating the skilled professionals who keep its planes, employees and customers flying safely and efficiently. Inspired by the pioneering work of Charles E. Taylor—the Wright brothers’ first mechanic, whose birthday is marked by AMT Day—Delta’s aviation maintenance technicians (AMTs) continue a legacy of excellence. Their expertise has propelled the airline into its centennial year and will drive Delta into the future of aviation.

Though often working behind the scenes, Delta’s AMTs play a key role in enhancing the customer experience by meticulously striving to maintain the nearly 980-aircraft fleet in peak condition and ready to fly.

Supporting a non-stop global operation, more than 6,600 Delta AMTs around the world bring passion, precision and pride to every task. Whether overseeing critical engine overhauls and testing at state-of-the-art facilities, maintaining the airline’s new interior renovations or pioneering industry-first drone inspections, these professionals form the core of Delta’s operations.

Diallo Harris, one of the technicians featured on Delta’s “Life at Delta” Instagram account, encapsulated the role by explaining that his daily inspections, repairs and engine replacements culminate in the rewarding moment when an airplane departs, secure in the knowledge that a safe product has been delivered for passengers.

The dedication of Delta’s AMTs is woven throughout the airline’s storied history. Whether in the spotlight or behind the scenes, they have played a crucial role in numerous milestones—from installing fast, free Wi-Fi across the fleet and launching flights to new global destinations, to inaugurating the world’s largest engine test cell in 2019. Above all else, the expertise and commitment of Delta’s AMT’s helps uphold the highest standards of safety and operational excellence in an industry that continually evolves—a responsibility embraced with pride.

“Happy AMT Day!”

On National Aviation Maintenance Technician Day, Delta celebrates more than just maintenance work—it honors a legacy of ingenuity, dedication and an unyielding commitment to excellence that has propelled the airline to its centennial milestone and beyond. The industry recognizes the indispensable role these professionals play, and Delta continues to offer rewarding career opportunities for aspiring technicians. Happy AMT Day to every technician whose dedication keeps Delta climbing.

Delta AMTs by the Numbers and through the Years

- 6,647 Delta AMTs

- 1,292 employees with more than 30 years of service

- 230,734 total components to be repaired in 2025

- 55,278 tires to be repaired in 2025

- 3,537 coffee/beverage makers to be repaired in 2025

- 2,283 veterans

- 980 aircraft

- 34 domestic stations, 11 international

- 907 Viasat installs, supporting fast, free Wi-Fi on Delta aircraft

1920s-1930s

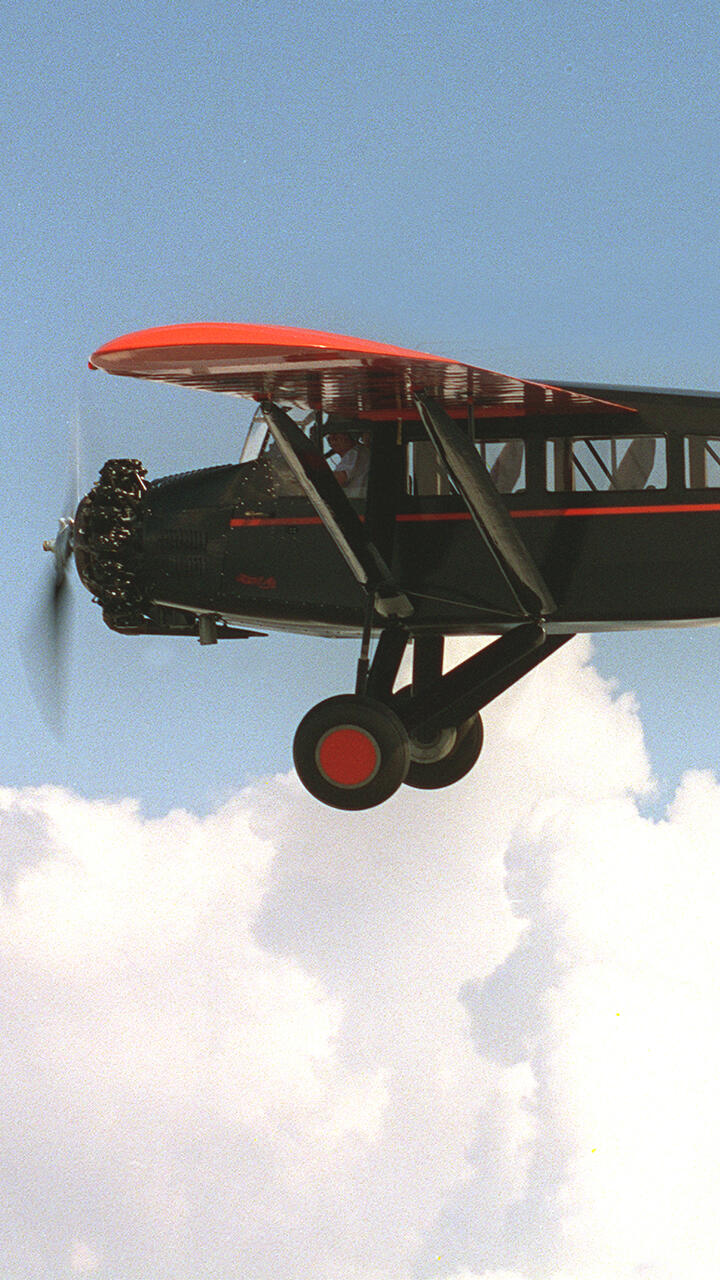

- 1925 – The Huff Daland Dusters crop-dusting operation, which formed the roots for Delta, begins in Macon, Ga. Incorporated on March 2, 1925, this was the first commercial aerial agricultural company in existence.

- 1929 – Delta Air Lines was established, marking the beginning of its long-standing commitment to safety and technical excellence. Although the maintenance division wasn’t formally branded as “TechOps” at this time, Delta’s heritage in aircraft upkeep and operational innovation takes root in this era.

- 1929 – Delta's maintenance division supports the airline’s inaugural flight, which took place on a Travel Air registered as C8878, manufacturer's serial number 988. A restored version of this aircraft is currently on display at the Delta Flight Museum.

1940s-1950s

- 1942 – Delta contributes to the war effort. The airline modified 916 aircraft, overhauled 1,000+ engines and instruments, trained U.S. Army pilots and mechanics, and operated cargo supply routes for the military.

1960s-1970s

- 1960 – Opened Jet Base in Atlanta, today's Technical Operations Center (TOC), for aircraft maintenance and overhaul that has the largest doors (open area) of any similar structure in the United States.

- 1972 – Delta TechOps completed its first expansion, increasing the overall land area to 142 acres (36 acres under roof) and also opened a new 194,000 ft hangar, spanning 785 ft wide, able to handle 2 Boeing 747s and 2 L-1011 jets.

1980s-1990s

- 1982 – Third Expansion of the TOC completed: Enlarged the original hangar, added a fourth engine test cell and expanded shop and warehouse areas. Total land area increased to 140 acres (over 42 acres under roof)

2000s-Present

- 2003 – Delta’s Technical Operations Center in Atlanta is first in the airline industry to achieve OSHA Star status for exemplary record of occupational employee safety and health.

- 2008 – Delta TechOps received ISO 9001 certification for its Component Maintenance shop in 2008.

- 2009 – Delta TechOps joined the EPA’s National Partnership for Environmental Priorities by committing to eliminate lead from machine shop operations and recycle over 7,000 pounds of lead.

- 2011 – Delta TechOps received ISO 9001 Certification for Engine Maintenance and Landing Gear Shops.

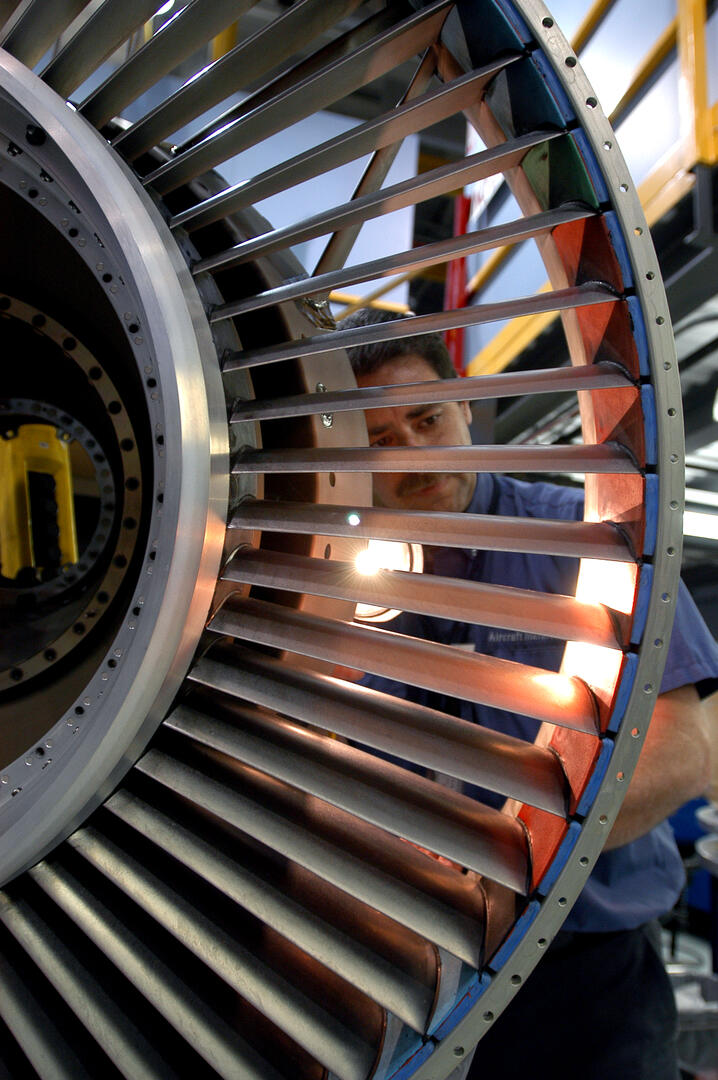

- 2018 – Delta Air Lines opened a 127,000ft2 repair shop by converting an aircraft hangar into dedicated engine maintenance space. This allows the team to perform maintenance on advanced-technology engines featured on Delta’s Airbus A350s and A330-900neo aircraft, and customer engines.

- 2019 – Delta opens world’s-largest commercial engine test cell in Atlanta

- 2023 – Opened state-of-the-art Pratt & Whitney GTF Engine Shop at our Atlanta facility

- 2024 – Delta becomes first in the industry to utilize drones for maintenance inspections.

- 2025 – Delta TechOps Celebrates 25 years of the launch of the DTO brand and MRO business.

About Delta TechOps

Delta TechOps is the backbone of Delta’s global operations, employing more than 13,000 people across 45 stations worldwide. Its team’s expertise spans line, cabin, engine and airframe maintenance, ensuring that each Delta flight is safe, efficient and ready for takeoff.

Beyond its technical achievements, Delta TechOps demonstrates a deep commitment to nurturing the communities it supports. Each year, Delta employees build bikes for local children through Toys for Tots, honor the U.S. military veteran community with Veterans Day celebrations, engage in Honor Guard activities and volunteer at the airline’s Military Lounge during the holiday season. This legacy of ingenuity, dedication and excellence has powered Delta into its centennial year and will sustain its climb into the future.

Delta TechOps also played an integral role in the major renovation of the Delta Flight Museum, ensuring that the historic hangars and iconic aircraft remain a testament to its century-long legacy. [Read more about the role some Delta TechOps team members had in the museum’s renovation.]

AMTs at Delta

A career as a Delta AMT offers an exciting entry into one of the industry's most rewarding fields. Delta's partnerships with more than 58 aviation maintenance schools nationwide open doors for aspiring technicians, while comprehensive training programs and hands-on experiences cultivate the next generation of aviation maintenance leaders. A Delta TechOps career not only delivers technical excellence but also offers long-term growth in an innovative and supportive environment. For more information on career pathways in aviation maintenance, interested candidates can visit TechU (deltatechu.com).