AMT Day: Meet the People who keep Delta’s planes flying

By Alex Koplin

National AMT Day honors the legacy of Charles E. Taylor, who became known as the "father of aviation maintenance” after serving as the mechanic for the first planes flown by the Wright Brothers. Since 2008, Delta Air Lines has celebrated National AMT Day on May 24 – Taylor's birthday – to recognize the unsung efforts of AMTs and the vital role they play in global air travel.

AMTs at Delta do more than turn wrenches. They masterfully service our fleet’s airframes, avionics, components, engines, interior cabin, logistics, inspections, engineering, planning and more. Beyond airplanes, Delta AMTs take pride in the culture of care they have for their communities, their peers and their planet.

Delta TechOps is made up of more than 6,400 AMTs around the globe – many of whom began their journey in aviation maintenance at a young age. To learn more about the pathways to a career in aviation maintenance, visit Home | TechU (deltatechu.com).

"The world-class expertise of our AMTs is essential to the safety and comfort of all Delta customers, and their commitment to excellence and servant leadership is unmatched,” said Mahendra Nair – S.V.P., Delta TechOps. “It’s an absolute honor to work alongside the aviation industry’s best maintenance professionals. They are a foundational piece of the Delta family.”

Read on to learn more about some of the AMTs who proudly wear the Delta TechOps uniform worldwide.

Wayne Tucek, AMT, Base Maintenance, Atlanta

“Getting to work with so many different talented and knowledgeable people is one of my favorite parts of my career. Everyone has the same goal — to keep our planes safe and dependable."

- A unique part about working in Base Maintenance is that Wayne spends time in the hangar to conduct “heavy maintenance” and routine checks on Delta planes.

- Wayne’s day typically consists of working on Boeing 717 engines. He helps change various filters, checks pneumatic valves and lines, and repairs them as needed. He also tests tail cone emergency systems to ensure proper safety for tail cone exits on Boeing 717s.

- When asked how he’d explain his role to someone interested in aviation careers, Wayne said: “When an airplane comes into the hangar for checks, many panels on the plane are opened from nose to tail, and AMTs inspect the entire plane and repair or replace parts as needed. I love that I play a role in that.”

Delta’s Base Maintenance team focuses on repairing airframes and interior modifications for Delta’s fleet and those of Delta MRO customers. Delta’s new free Wi-Fi systems were installed by the Base Maintenance team.

Carolina Rodriguez – Lead AMT, Cabin Maintenance, Boston

“As an AMT, there are so many opportunities to move to different areas and grow your career at Delta. From Line Maintenance and Cabin Maintenance to the shops and hangar work, we have an abundance of options to pursue, and Delta gives us the freedom to choose that path.”

- Something unique about AMTs is that aside from getting licenses to work on planes, they also must get qualifications for different fleets within Delta. Carolina loves that there is a never-ending cycle of learning, and to her, that’s why being an AMT is so rewarding.

- As a Lead AMT, Carolina’s day consists of scheduling and assisting her team with accomplishing Cabin Maintenance tasks inside the aircraft. She also ensures the Boston team remains compliant with safety and training and leads the way in recognizing her peers.

- Carolina describes her role to those interested in aviation careers as leading a team that performs preventative maintenance for anything a passenger sees, uses or touches, like the seatback screens onboard.

Delta’s Cabin Maintenance team services items inside the interior (cabin) portion of Delta aircraft, like seats, lavatories, in-flight entertainment screens, tray tables and more.

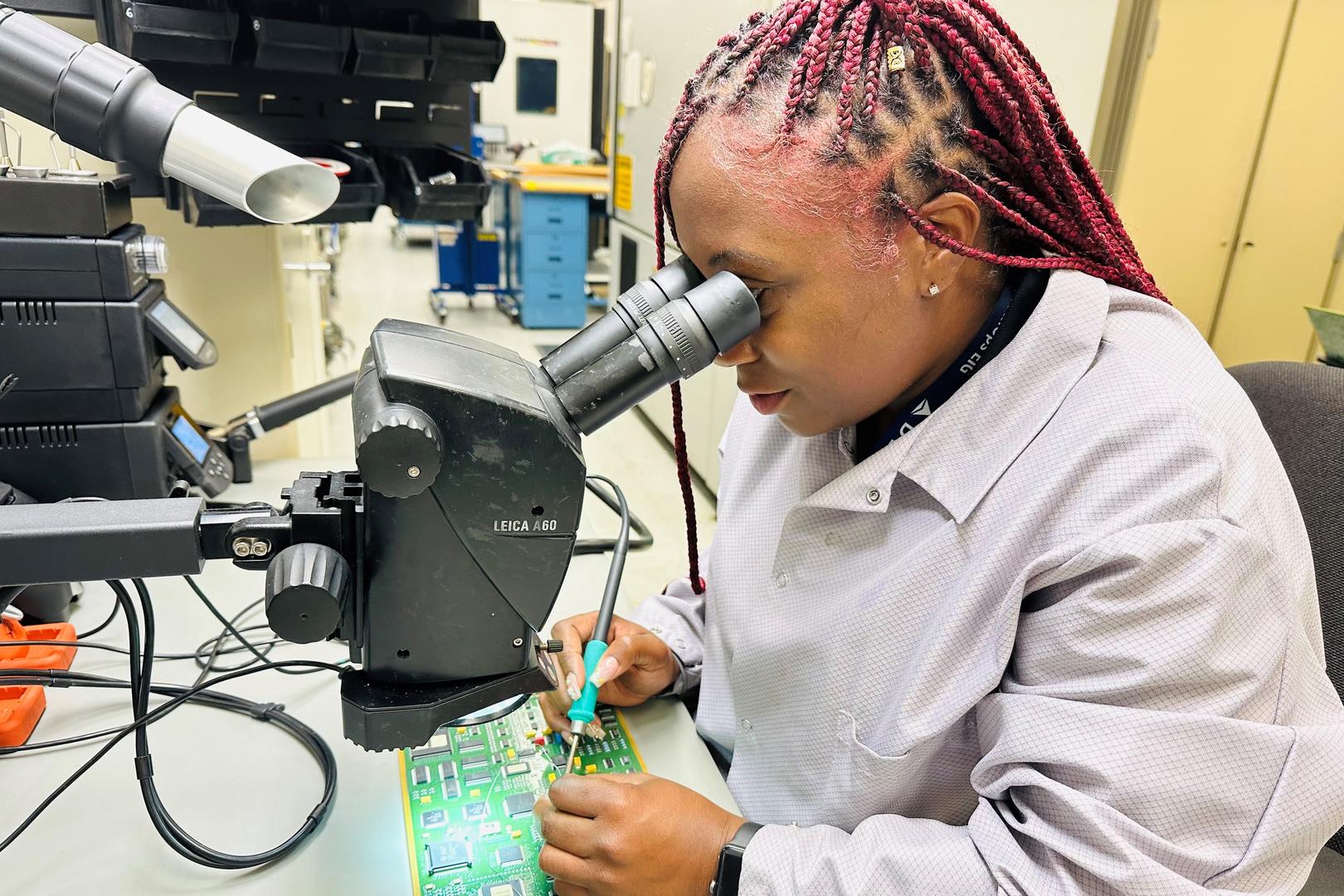

Joy Christian – AMT, Avionics, Component Maintenance, Atlanta

“My favorite part of being an AMT is the sense of pride I get once I fix a unit to send back to an aircraft. To see a plane in the air and know that I once repaired a component on that plane to get our customers to their destination is a special feeling.”

- Something unique about being a Component Maintenance AMT is that TechOps has a specific shop for every component part of the airplane. From repairing wheels and brakes to flight computers, AMTs can do it all. In Avionics, Joy works with the “brains” of the plane.

- Joy’s primary responsibility is to troubleshoot and repair flight computer systems on the Airbus line.

- Joy describes her role to those interested in aviation careers as being responsible for performing necessary repairs on aircraft components – whether it’s scheduled or unscheduled maintenance – in order for the plane to fly.

Delta’s Component Maintenance team repairs aircraft component parts, like hydraulics, batteries, sheet metal and radomes, on Delta and MRO customer aircraft.

John Graff – AMT, Engine Maintenance, Minneapolis Engine Shop

“I love airplanes and I love history, so being at Delta TechOps for 44 years has allowed me to see a lot of both.”

- A unique part of John’s job is working on massive engines for both Delta aircraft and MRO customers. Another interesting fact about AMTs is that they hold Federal Airman Licenses.

- Alongside being an AMT, John serves as an Operational Safety Leader, so part of his day includes leading safety and compliance efforts for his Engine Maintenance peers at MSP.

- To someone interested in an aviation career, John describes his job as keeping vehicles flying safely so Delta can get customers to their destinations.

Delta’s Engine Maintenance team performs repairs on Delta and MRO customer aircraft engine platforms like CFM International, Pratt & Whitney, Rolls-Royce and GE Aviation.

Alexander Spencer – Inspector, Engineering, Quality and Safety, Minneapolis

“Getting to experience the overall adventure that this career field will take you on is what I love most about being an AMT. I’ve been fortunate to travel the world, form relationships with peers that will last a lifetime and contribute to projects that are much bigger than me.”

- To Alexander, something unique about AMTs is that they have a very fine eye and attention to detail. Aircraft maintenance comes with a different level of responsibility because when a plane is in the air, it can’t just pull over to a repair shop like most motor vehicles can.

- As an Inspector, Alexander is responsible for ensuring compliance with FAA regulations that maintenance operations fall under. His day typically consists of engine borescope inspections, which use a tube equipped with a microscopic camera to check hard-to-reach areas of engine interiors for defects or damage. Alexander also conducts non-destructive testing, inspections for flight critical aircraft components, inspection buy-backs on maintenance tests and inspections to find defects on Delta planes upon their entry into heavy checks.

- To someone interested in an aviation career, Alexander describes his job as being the last line of defense for Delta’s aircraft before they return to the skies after undergoing maintenance.

Before returning an aircraft to service, Delta’s Inspections team ensures the quality and compliance of Delta aircraft during heavy maintenance checks in the hangar.

Rocco Resce – AMT, International Line Maintenance, London

“I always wondered what ‘The Delta Difference’ meant, but when you start spending time with Delta people, you completely understand the definition. As an AMT in Europe, I get to work with so many great people from all walks of life, and that’s one of my favorite parts of being an AMT.”

- A unique part about being a Line Maintenance AMT in London is that Rocco routinely travels to other airports in Europe to help with maintenance tasks on widebody aircraft like the Boeing 767, Airbus 350 and Airbus 330.

- Rocco’s day as a Line Maintenance AMT typically consists of maintaining, inspecting and repairing aircraft while at a gate (on the line). Line Maintenance AMTs have to complete pre-departure checks on planes before they take off, and tasks typically range from repairing fuel and hydraulic fluid leaks to completing complicated electronics and component repairs.

- To someone interested in an aviation career, Rocco describes his job as working as an airplane doctor. When airplanes break, AMTs fix them by following manuals, processes and procedures along the way – always with safety for our customers, our planes and our peers top of mind.

Delta’s Line Maintenance team has a worldwide presence and performs scheduled and unscheduled maintenance checks and repairs for Delta’s fleet in between flights, overnight while parked at the terminal or when an aircraft is out of service.